LEKA restaurant

Parametric acoustic ceiling system for a tessellated origami structure

Client: Leka

Developer: FAB Lab Barcelona

Fabrication team: Miguel Guerrero, Anastasia Pistofidou

Photography: Javier Callejas, Miguel Guerrero

Animation: Miguel Guerrero

Parametric design: Rodrigo Aguirre

Overview

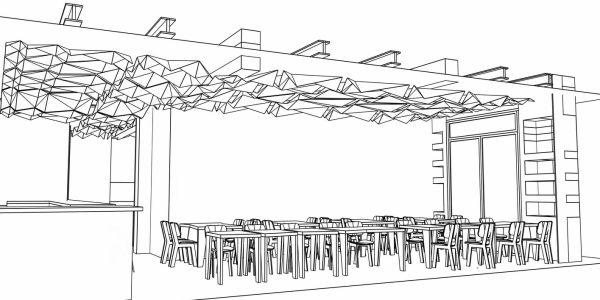

LEKA is a restaurant built locally in the 22@ district of Poblenou, Barcelona, developed and fabricated at Fab Lab Barcelona in collaboration with a network of local craftspeople and suppliers. Conceived as an open-source platform, the project shares all the knowledge that defines it—from the recipes and nutritional advice to the design and fabrication of its physical elements. Everything is downloadable and replicable.

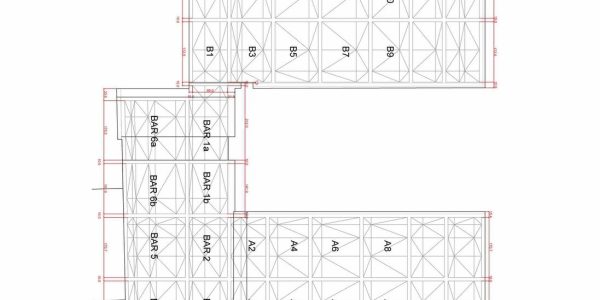

The space is organized around distinct design families—furniture, acoustic elements, interactive features, and more. Each required a tailored construction strategy: robust systems for furniture subject to heavy use, lightweight geometry to break up sound reflections in the ceiling, and carefully perforated wall panels to absorb acoustic energy. To approach this, each family was developed through a programmable design strategy, creating adaptable, modular systems. This allowed for fabrication-ready outputs that remained true to a shared design language.

Acoustic Elements

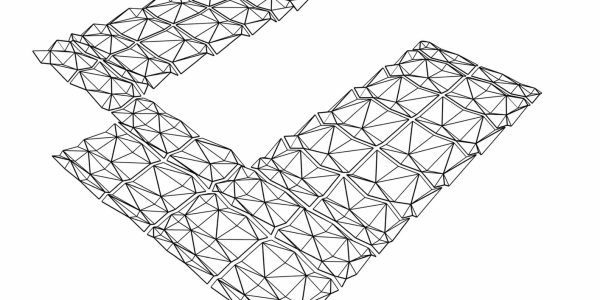

The acoustic ceiling was inspired by origami techniques, creating a surface that is both lightweight and structurally rigid. Its acoustic behavior stems from its folded geometry, which breaks sound waves and reduces reverberation. Suspended beneath a layer of rock wool, the system works by both reflecting and absorbing sound.

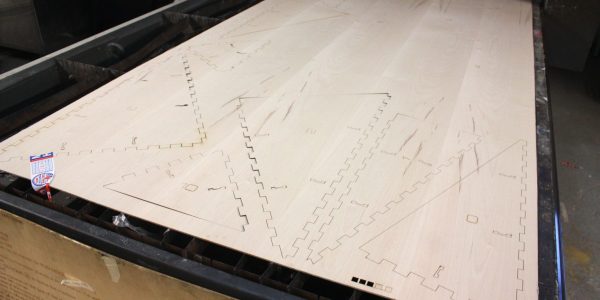

Constructed from ultra-thin 3.5 mm birch plywood sheets, the ceiling panels are assembled using an interlocking pressure-fit system—a kind of 3D puzzle that allows for easy on-site assembly. Thanks to their geometric rigidity, only a few hanging points are required, simplifying installation.

Along the walls, a second acoustic system draws a fluid line, echoing the ceiling geometry. These panels incorporate conical perforations that guide sound waves inward, where they are absorbed by a mineral wool substrate.

From Complexity to Fabrication

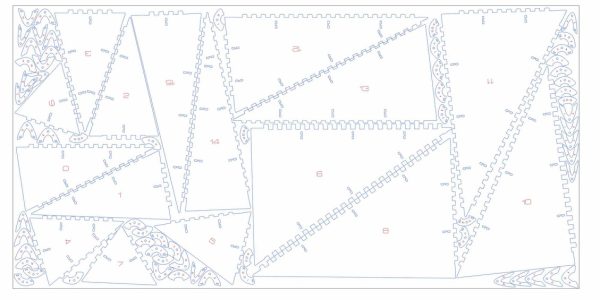

A fully parametric system was developed to translate the geometric concept into a fabrication-ready logic. This system automated the generation of the individual origami components, embedding both structure and precision directly into the digital model.

The ceiling consists of 34 unique triangular panels, each subdivided into 12 interlocking pieces—more than 400 parts, each defined with custom finger joints and labeled with a unique identifier. The parametric workflow allowed for real-time adjustments, adapting to fabrication constraints while ensuring consistency and avoiding errors during assembly.

By tightly integrating design, structure, and digital fabrication, this system allowed the team to move seamlessly from digital prototypes to 1:1 mockups—bridging concept and construction with high fidelity. It reflects a way of working where geometry, performance, and process are deeply intertwined—enabling complex, adaptive architecture without compromising buildability.