Metallic spaces

Robotic Rod Bending Pavillion

GSS Director: Aldo Sollazzo

GSS Coordinator: Laura Ruggeri

GSS Bcn Lead Tutor: Rodrigo Aguirre

Robotic Fabrication Tutor: Kunal Chadha

Physical Computing Tutor: Cristian Rizzuti

Student Assistants: N. Mougkasi, S. Garavani, D. Koshelyuk, A. Talaei, A. Najari, H. Mahdi, A. Mittal, S. Jalodia, N. Kirova, A. Jain, L. Teodozio, R. Jiale

Students: R. Rode, L. Cavichioni, G. Bratkowska, M. Busairi, A. Babic, C. Tucker, J. Rangholiya, D. Muhsen, S. McNair, F. Apestegui, M. Castillo, D. Gransewicz, T. Sakaguchi

Video: Nikoleta Mougkasi

Overview

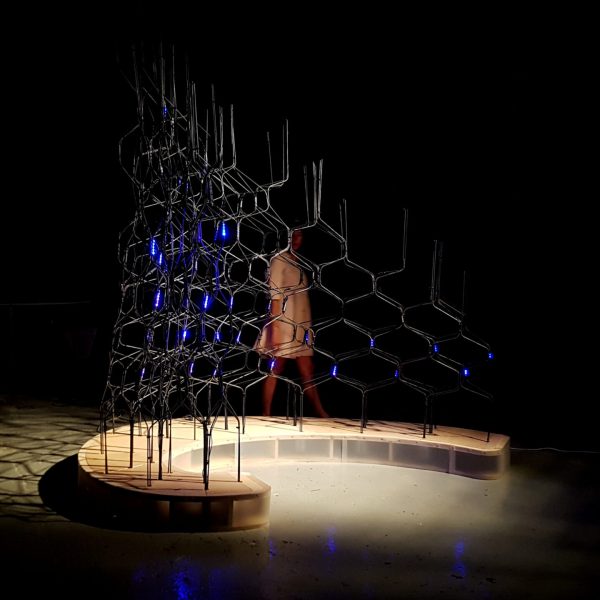

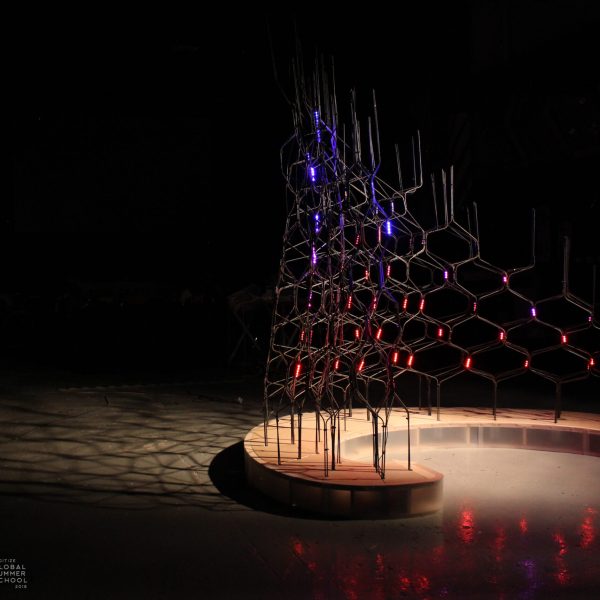

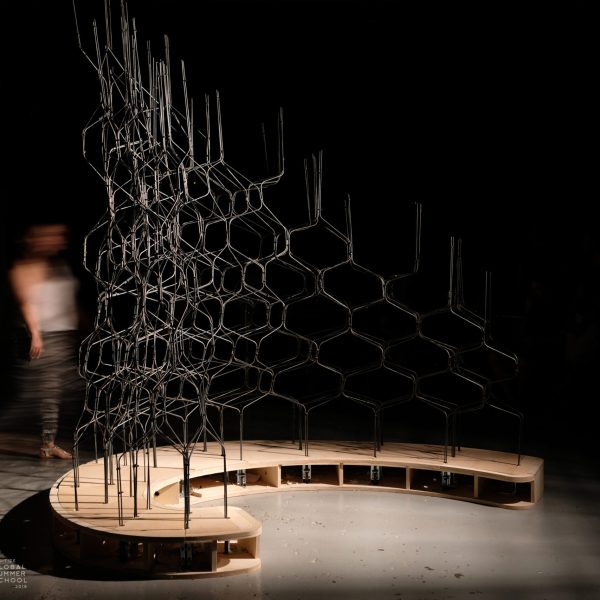

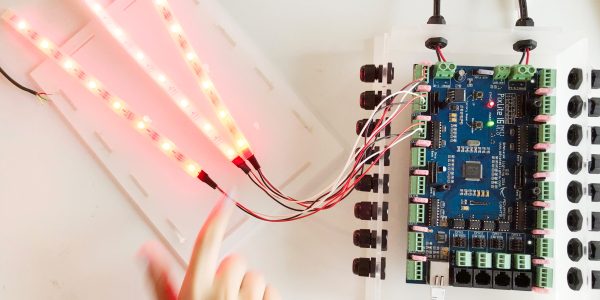

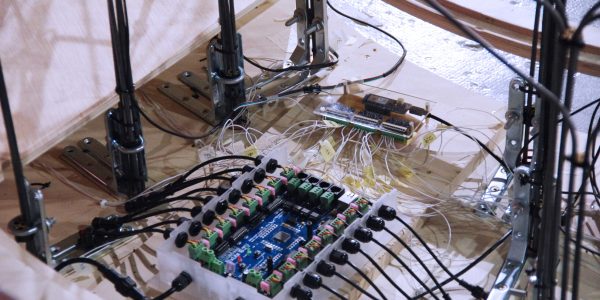

Metallic Spaces is a 1:1 architectural prototype that merges computational design, robotic fabrication, and physical computing into an expressive, interactive structure. Composed of robotically bent steel rods, the pavilion defines a translucent spatial envelope embedded with touch-sensitive elements that respond with sound and light. The result is a responsive installation that reimagines how users interact with public space—shifting it from a passive environment to an active interface.

Developed during the Global Summer School at IAAC, Barcelona, Metallic Spaces is the result of a two-week intensive workshop exploring advanced design strategies and large-scale robotic manufacturing. Participants investigated the feedback loop between digital modeling and physical realization, engaging in hands-on experimentation across computational design, robotic toolpath generation, and interactive systems.

The ambition was to explore how matter, motion, and data could be fused into an adaptive spatial prototype that speaks the language of contemporary urban interaction.

From Computation to Fabrication

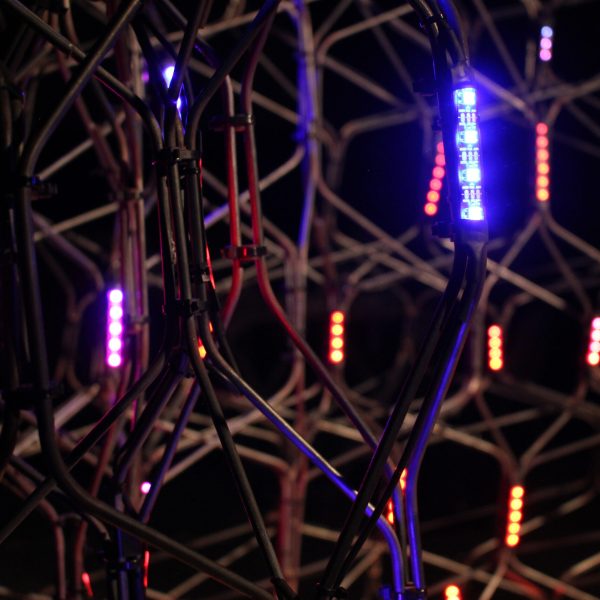

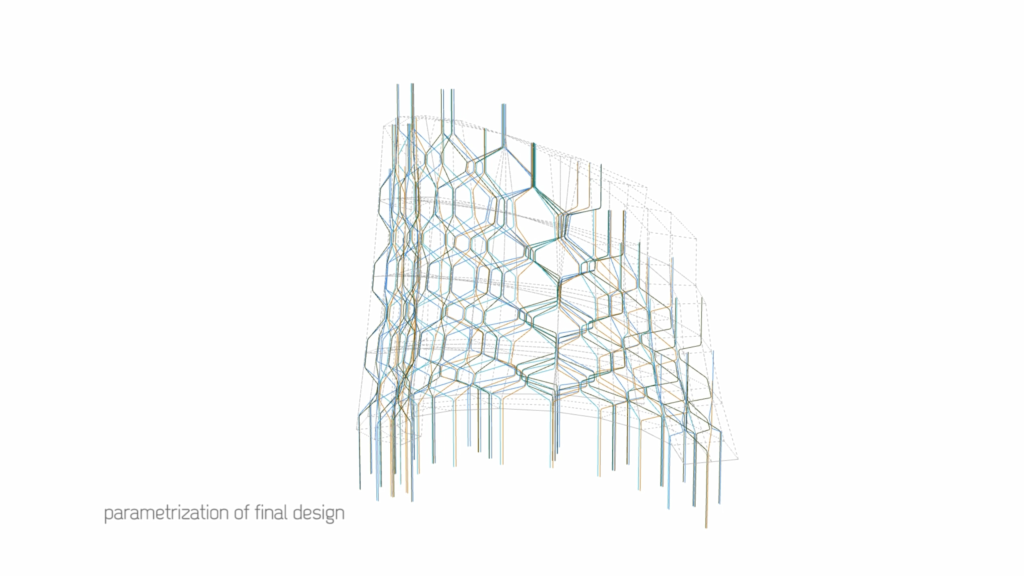

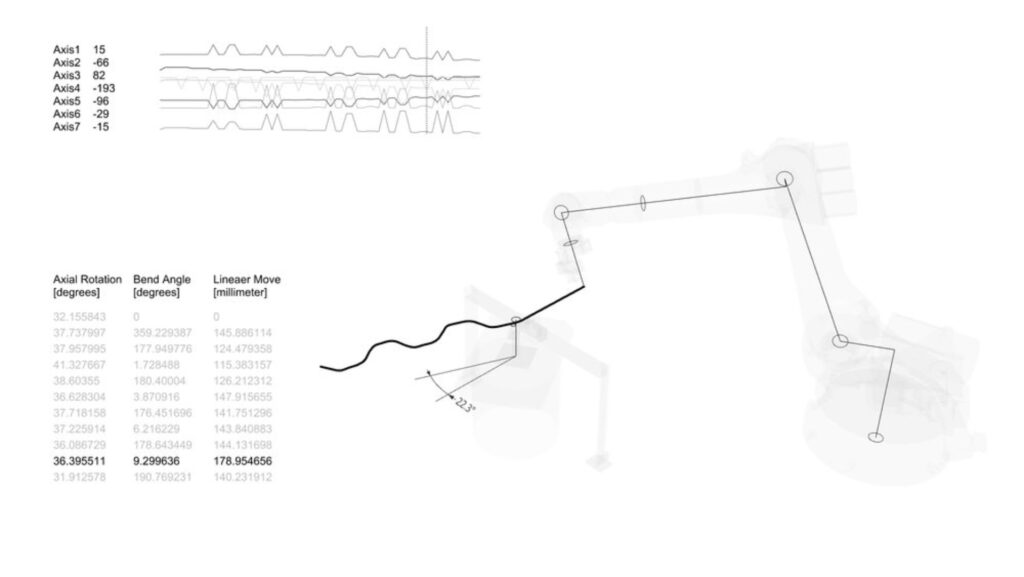

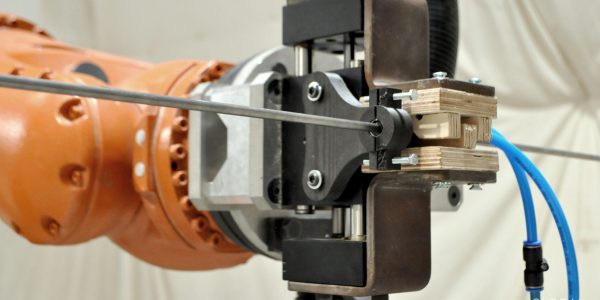

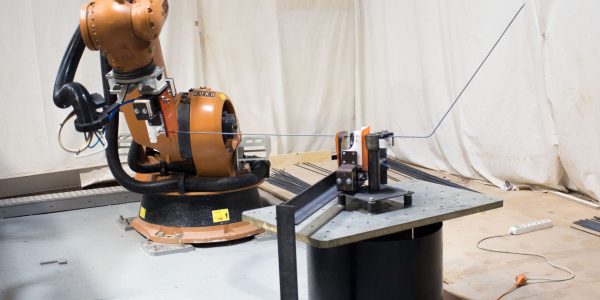

The pavilion’s design is grounded in a fully digital workflow, where computational logic governs every aspect of the process—from geometric definition to robotic execution. The structure’s primary material, steel rod, is manipulated using a 7-axis KUKA robotic arm, enabling precision-bending of complex geometries that defy conventional methods.

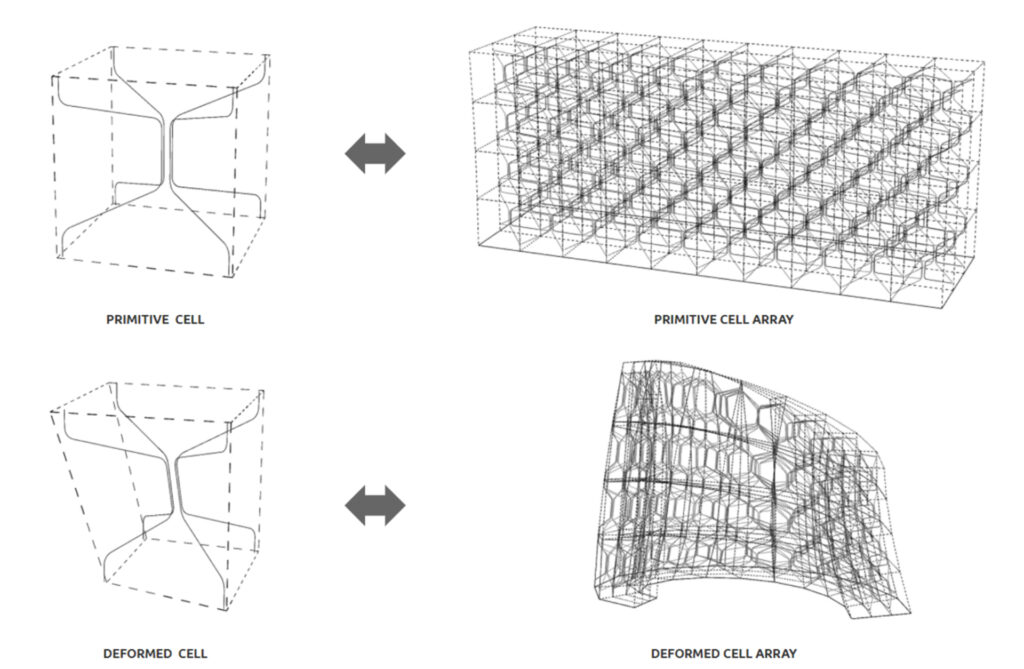

At the core of the computational process lies a modular system. A base unit was defined and propagated into larger assemblies using cellular arrays and morphing techniques. Attractor points informed local variations, introducing structural and spatial differentiation driven by contextual data. These variations were optimized through reparametrization to ensure fabrication feasibility, while maintaining design intent.

Robotic Fabrication Process

Every rod in the pavilion was bent following toolpaths derived directly from the parametric model. This digital-to-physical pipeline allowed for rapid iteration, with robotic motion fine-tuned to match the material’s behavior. Jigs and fixtures were CNC-milled to ensure precise assembly, while interactive components—programmed through microcontrollers and embedded sensors—brought the structure to life through tactile feedback.