ACCIONA 3dp bridge

Parametric concrete bridge created through large-scale 3D printing

Client: Alcobendas City Council

Construction Company: ACCIONA

Design Team: Areti Markopoulou, Rodrigo Aguirre, Alexander Dubor, Jayant Khanuja

Collaboration: D-Shape – Enrico Dini

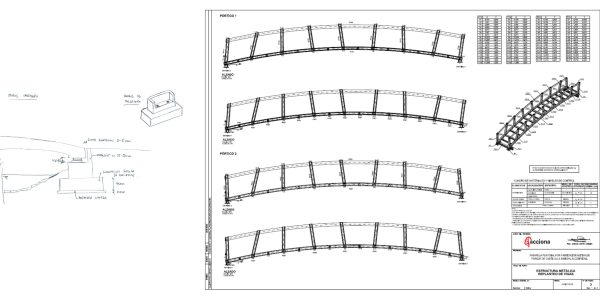

The 3D Printed Bridge in Alcobendas, Madrid, marks a groundbreaking step in the evolution of digitally fabricated infrastructure. Designed by IAAC and built in collaboration with ACCIONA, it is the world’s first 3D-printed pedestrian bridge in micro-reinforced concrete. Spanning 12 meters, the bridge integrates seamlessly into the Castilla-La Mancha urban park, offering both functional connectivity and a glimpse into the future of computationally driven public works.

More than a pedestrian path, the project serves as a research prototype for digital public works, pushing the limits of what infrastructure can be when design, analysis, and production are truly integrated. It demonstrates how parametric thinking, agent-based modeling, and advanced fabrication can produce architecture that is not only efficient—but alive to its context.

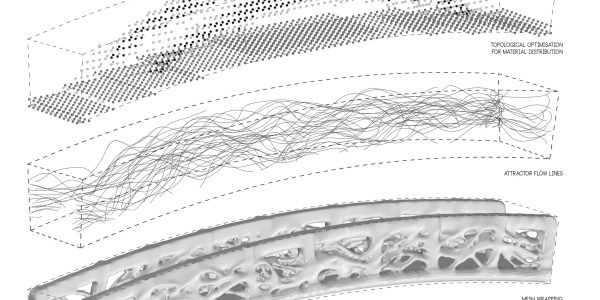

Computational Design Process

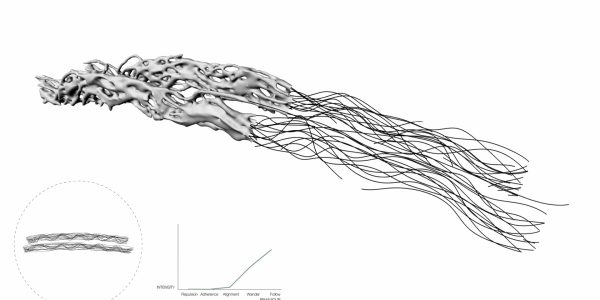

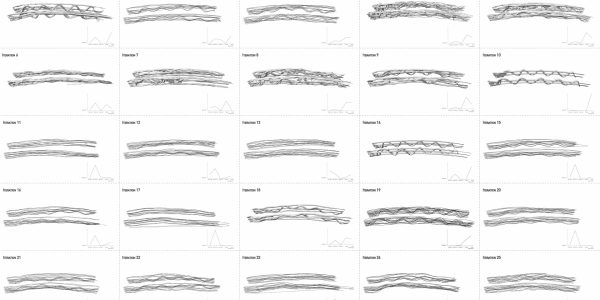

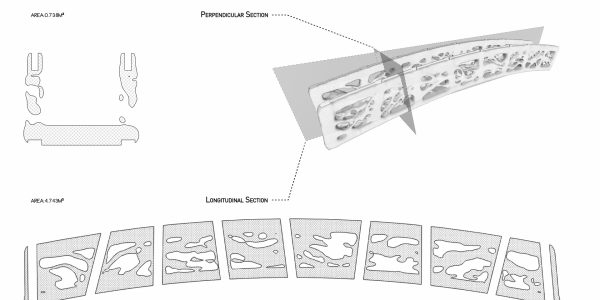

The bridge was developed through a fully parametric workflow that integrated structural logic, spatial performance, and fabrication constraints into a single generative system. Instead of designing form and performance separately, the process allowed geometry, structure, and material behaviour to evolve in parallel. Performance-based simulations informed the global curvature and section profiles, ensuring that structural efficiency and spatial qualities were embedded from the outset.

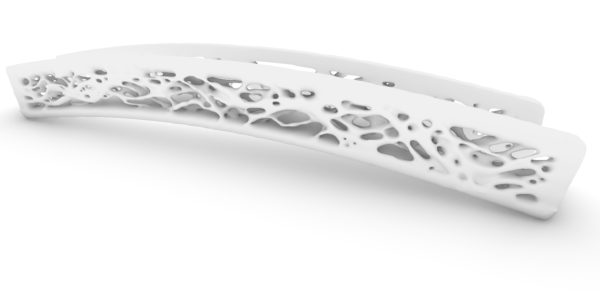

At a more detailed scale, agent-based simulations introduced controlled porosity where structural demand decreased or acoustic transparency was required. These behaviours enabled the geometry to adapt locally, balancing efficiency with experiential qualities. Topological optimization further reduced material usage, while curvature-driven force flows guided load distribution. Finally, the bridge was discretised into stereotomic pieces, each designed for modular fabrication and reinforced by a hidden steel structure—seamlessly linking computational logic to constructability.

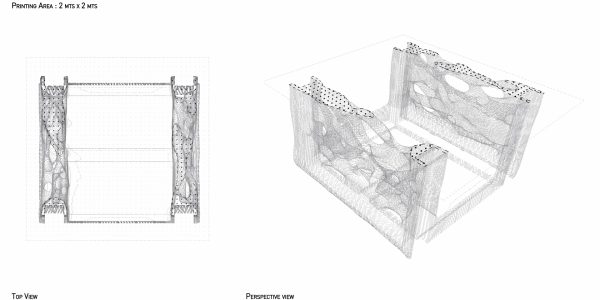

3D Printing

Each concrete component was robotically 3D printed using a micro-reinforced mix. The design was broken down into stereotomic blocks, parametrically defined to fit assembly tolerances and embed support logic. These blocks interfaced with a steel reinforcement framework, creating a hybrid structure that combines the adaptability of digital fabrication with the strength of conventional systems.

The additive fabrication strategy eliminated the need for traditional formwork, significantly reducing waste. By integrating porosity as a functional feature—for both structure and sound—material usage was minimized and performance enhanced. The bridge stands as a proof-of-concept for scalable, sustainable public infrastructure designed through computation.