bb make

A Collaborative and Open Structure

Workshop director: Areti Markopoulou

Coordination: Mathilde Marengo, Maria Kupstova

Pavilion Design: Rodrigo Aguirre

Fabrication development: Alexandre Dubor

Local collaborators:

Central Academy of Fine Arts (CAFA, Beijing)

Tongji University (Shanghai)

Overview

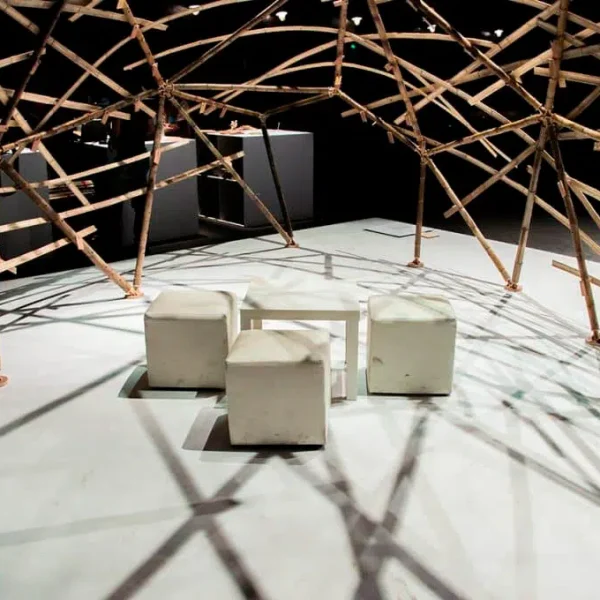

In 2014, as part of Beijing Design Week, Barcelona was invited as the guest city under the theme “Barcelona, a Future Inspired by Design.” The exhibition took place in the iconic 79-Tank industrial complex, where the Institut Ramon Llull selected the Institute for Advanced Architecture of Catalonia (IAAC) to represent the city with its project: BB MAKE – Barcelona Beijing Make.

BB MAKE was a collaborative installation developed by IAAC in partnership with the Chinese Academy of Fine Arts (CAFA) and Tongji University. The project explored the fusion of traditional materials with cutting-edge digital fabrication technologies, promoting a participatory, open-source design approach.

The pavilion embodied a living, evolving architecture—a convergence of material culture and digital innovation. It served as a platform for knowledge exchange, bringing together traditional craftsmanship and advanced fabrication tools in a shared creative process. The project demonstrated how collaborative, open-source design can empower communities, turning fabrication into a collective experience.

Fabrication System

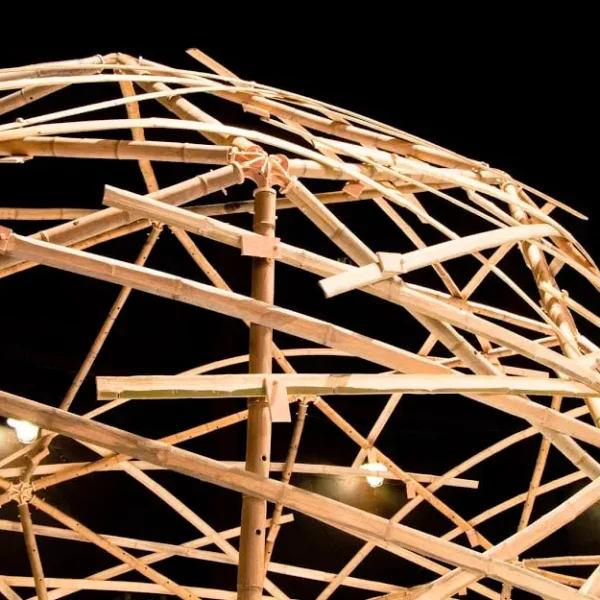

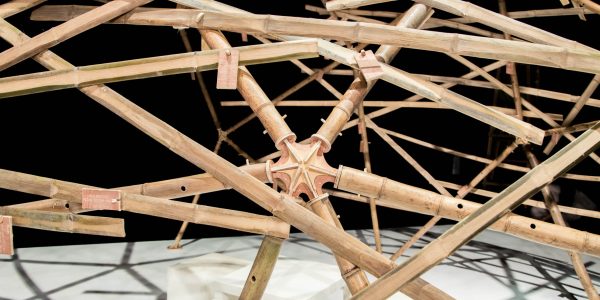

At its core, the structure consisted of natural bamboo beams—a widely available local material—joined together using custom digital joints, fabricated on-site through 3D printing and CNC milling. The custom joints were developed to accommodate the natural irregularities of bamboo, ranging in diameter from 40 to 60 mm, allowing the structure to adapt and grow easily.

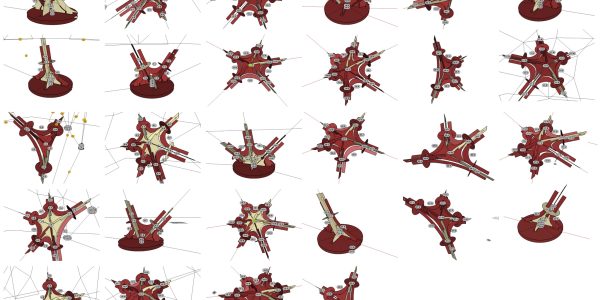

The joint system was designed during a week-long workshop held at CAFA, involving 15 local architecture students. This process introduced students to parametric modelling, digital fabrication, and open-source design workflows. Together, participants designed, tested, and fabricated a press-fit joint system, resulting in 22 unique joint variations that held the structure together.

Building Together

The structure was assembled during Beijing Design Week with the help of students, professionals, and members of the public. Visitors were not only spectators but active builders, contributing to the final form. A secondary layer of the structure used split bamboo beams, allowing visitors to CNC mill personal messages and attach them to the main structure, creating a tangible imprint of participation.

To facilitate this process, IAAC set up a pop-up Fab Lab within the 79-Tank venue, equipped with CNC machines and 3D printers, enabling real-time fabrication and learning.