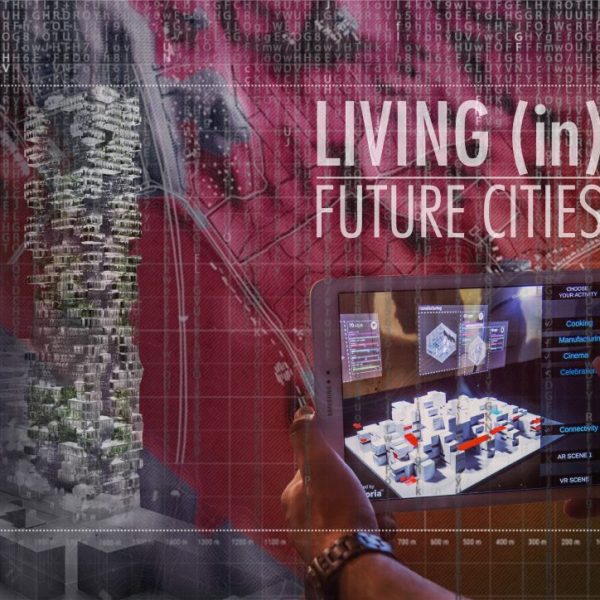

Living (in) Future Cities

Parametric Modularity for Adaptive Exhibition Design

Coordination & Exhibition Design: Lili Tayefi

Project Management: Rodrigo Aguirre, Silvia Brandi, Marco Ingrassia

Computational development: Rodrigo Aguirre

Production: Pietro Avanzino, Jayant Khanuja, Raimund Krenmueller, Maria Kuptsova, Alfredo Mamani, Angel Muñoz, Anna Popova

Content Curation: Areti Markopoulou, Mathilde Marengo, Maria Kuptsova, Marco Ingrassia

Communication: Gerard Fernandez, Alice Puleo, Lina Salamanca, Lennart Wirfs

Drawings: Lili Tayefi

Overview

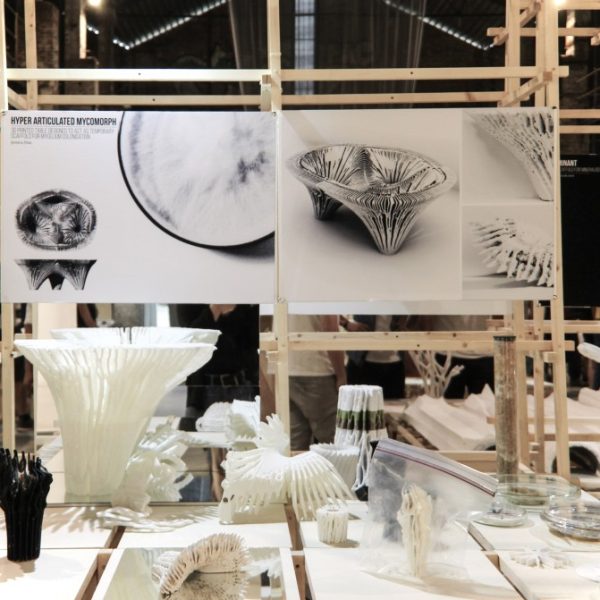

As part of IAAC’s annual public exhibition, Living (in) Future Cities presented a wide selection of research from its Master programs—MAA, MaCT, MAI, and OTF. The work ranged from material experimentation to urban-scale proposals, exploring how technology can shape the spaces we inhabit.

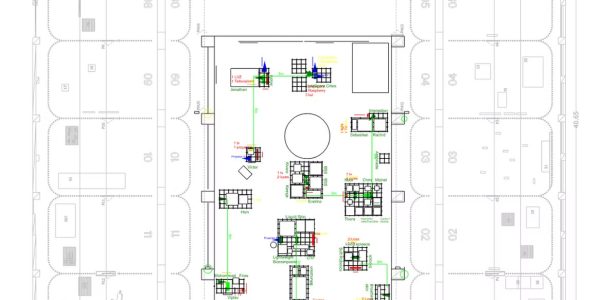

The exhibition was held in a 200-square-meter industrial hall at MUHBA Oliva Artés, under strict spatial constraints: no contact with walls or ceilings, no fixed lighting or hanging elements, and an unknown set of over 50 prototypes to be accommodated on-site. These limitations required a computationally-driven solution that could rapidly adapt to changing inputs while maintaining a cohesive and legible spatial narrative.

Computational Design & Fabrication Workflow

To address this complexity, we developed a fully digital workflow that automated the entire process—from design to fabrication. At its core was a parametric furniture system designed to generate modular, self-supporting display islands. Using Rhino and Grasshopper, we built an interactive stacking interface that allowed users to arrange virtual elements, instantly triggering the generation of all structural components and CNC-ready cutting geometries.

This system offered:

- A visual interface to design custom display modules in real time

- Automated generation of parts, bill of materials, and optimized nesting layouts

- Immediate visualization of structure, dimensions, and stability

- Standardized tool-less joints for rapid on-site assembly

- Fabrication-ready outputs for 2D milling and CNC production

Each configuration responded intelligently to prototype dimensions and curatorial needs, enabling flexibility without compromising clarity or speed. The result was an elegant, modular display environment built entirely in-house within a tight 6-week timeline and limited budget.

By integrating parametric design with automated fabrication logic, we created an intuitive and scalable system that translates curatorial content into a physical environment adaptable and efficient to build.